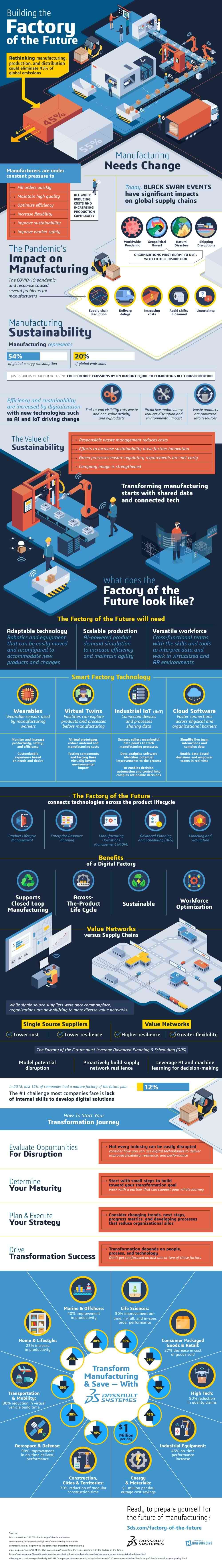

The world of manufacturing is never constant as competition and consumer demand continuously affect how manufacturers approach their work. Manufacturers are under pressure to fill orders quickly, maintain high quality, optimize efficiency, and improve worker safety while reducing costs and increasing production complexity. Black swan events like a worldwide pandemic, geopolitical unrest, natural disasters, and shipping disruptions add more problems for manufacturers. However, the factory of the future can help enhance production and meet customer expectations by combining the virtual world with the physical through resource planning, manufacturing planning, planning and optimization, and manufacturing and operations.

The factory of the future will need to include cross-functional teams, AI-powered product demand simulation, and movable robotics and equipment to increase efficiency and adapt to virtual environments as well as new products. Incorporating smart factory technology such as industrial IoT and Cloud Software will also help maximize flexibility and agility through digitization. A digital factory connects technologies across the product life cycle so the workforce can be optimized, closed loop manufacturing is practiced, and sustainability is increased.

The biggest challenge most companies are facing in terms of creating a practical factory of the future plan is a lack of internal skills necessary to generate effectual digital solutions. The ability to evaluate possible sources of disruption will allow you to determine your maturity as a manufacturing company. Being able to identify changing trends and interpret progress metrics will further allow you to plan and execute a strategy that drives transformation and success.